how is stress related to density microindentation hardness tester|micro hardness testing : specialty store Two broad categories of microindentation hardness testing can be identified: (1) quality control and process development, and (2) research, both basic and applied. WEB26 de dez. de 2021 · MSM: The Lost Landscapes. Add to. My games. 290. Add to. Wishlist 87. Save to. Collection. Exceptional. 118 ratings. Click to rate. Exceptional. 72. Recommended. 34. Meh. 3. Skip. 9. Write a .

{plog:ftitle_list}

WEB😈😈 grupo aberto todoz os dias !!😈😈 sem regras!! c.🅿️🐾🔞 tudo liberado ️ -----

Microindentation Hardness Selection criteria as they relate to microindentation testing are as follows: Hardness range of test material – A wide range of material types and hardnesses can be evaluated. Additional criteria are necessary when working with plastics, transparent materials, .Microhardness testing can be defined as indentation hardness testing that involves applied loads of 1 N or less on the indenter or, more precisely, as tests which result in indentation depths of .The effect of the test load on the sensitivity to stress of the diamond pyramid hardness (DPH) was investigated on a martensitic spring steel, a Type 304 stainless steel, and an aluminum .Two broad categories of microindentation hardness testing can be identified: (1) quality control and process development, and (2) research, both basic and applied.

Metallographers and failure analysts use the meth-od for a host of purposes including evaluation of homogeneity, characterization of weldments, as an aid to phase identification, or simply to . Microindentation hardness measurements showed gradients with the center of the wire measuring 359 ± 6.4 HK (HP) and 329 ± 7.2 HK (SP) while mid-radius values were similar for both at 366 ± 5.1.Microindentation hardness numbers depend on a combination of surface and bulk material properties. As indenter geometry and test loads are changed (particularly at loads below about . Microindentation hardness testing (MHT) is a very valuable tool for the materials engineer, but it must be used with care and a full understanding of potential problems. The purpose of MHT is.

In this paper, the major methods used to measure the indentation hardness of materials at different scales are compared, and main issues and misconceptions in the .A test often gives a “number”, which has all sorts of units; a few of these numbers can be understood in terms of more standard unit - Pa Hardness is a complex outcome of elastic, plastic and viscous properties of material. Under certain test .Microindentation hardness testing (or microhardness testing) is a method for measuring the hardness of a material on a microscopic scale. A precision diamond indenter is impressed into the material at loads from a few grams to 1 kilogram. The impression length, measured microscopically, and the test load are used to calculate a hardness value.

Standards Related to Microindentation Hardness Testing A considerable number of international standards for con ducting microindentation hardness testing exist. Most are found in three sources: DIN (W. German), ISO, and ASTM. The DIN standards for Vickers and Knoop test ing are 50133 and 52333, respectively. The ISO lists three The ISE of hardness was commonly explained by Nix–Gao's geometrically necessary dislocation (GNDs) model [9].However, many researchers, such as Swadener et al. [10] and Feng et al. [11], have reported overestimations of hardness for small indentation by Nix–Gao's model.They explained the overestimations as follows: due to strong repulsive force, .quality of microindentation test results [ 6]. In the early days of low-load (< 00gf) hardness testing, it was quickly recognized that improper specimen preparation may influence hardness test results. Most text books state that improper preparation will yield higher test results because the surface contains excessive preparation induced deforma-

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Microindentation hardness testing (or microhardness testing) is a method to measure the hardness, modulus, and several other properties of a material on a microscopic scale. . Elastic modulus is the ability of a material to “bounce back” after applying stress. By its control and recording of force and displacement, IIT can provide the .This article provides a discussion on the equipment used and specimen preparation for microindentation hardness testing (MHT) such as the Vickers hardness test and the Knoop hardness test. . Related Book Content. Process Capability and Tolerances. Steel Castings Handbook (Sixth Edition) Overview of Wear and Erosion Testing of Coatings.The basis of each Instrumented Indentation Tester is Step, a versatile surface testing platform providing housing for different types of indentation and scratch testing heads, thus covering up to four types of testing possibilities: instrumented indentation testing, scratch testing, Vickers hardness, and basic tribology.

ultrasonic micro hardness testing

Nanoindentation, also called instrumented indentation testing, [1] is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material. [2]According to the standard test method from the American Society for Testing and Materials and previous studies 15, 16, the procedure was defined by a load of 50 gf, the indentation time was set to 50 s, and the dwell time was set to 12 s. The hardness value (HV) was computed for each indentation. Hardness ValueThe hardness in the micro test is the mean of the stress of the object due to indentation. 3. Advantages and Disadvantages of Micro Hardness. Advantages of micro hardness. It can measure the hardness of thin layers; in the micro hardness test, only u one type of indenter is used; A MIcro hardness test can also utilize of Non-destructive tests Hardness versus load curves show trends similar to those of Young’s modulus. However, unlike the Young’s modulus, the hardness values measured under the same load can be directly used to rank .

Residual stress engineering is widely used in the design of new advanced lightweight materials. For metallic glasses, attention has been given to structural changes and rejuvenation processes.

The presence of residual stress seriously affects the mechanical performance and reliability of engineering components. Here, the authors propose a novel method to determine corresponding residual stress through micro .

Microhardness testing or microindentation hardness testing is often applied to measure the hardness of a sample on a microscopic scale. . which have the dimensions of stress, load P and diagonal length d are measured in gf and µm, respectively. The first equation is based upon the surface area of the impression; the second is based upon its . Low-Load Vickers Microindentation Hardness Testing. April 2012; AM&P Technical . Because this is a visual p erception problem related to. . the density of 6 plies and 8 plies recorded 1.541 .

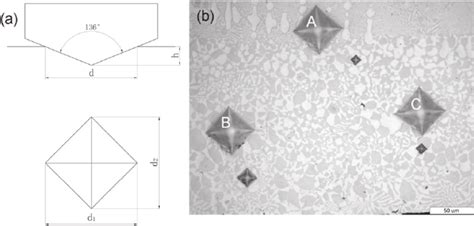

Vickers hardness test. The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. The Brinell, Vickers, Meyer, Rockwell, Shore, IHRD, Knoop, Buchholz, and nanoindentation methods used to measure the indentation hardness of materials at different scales are compared, and main .

The result shows that mesoscopic elastic modulus and indentation hardness increase nonlinearly with the increase of the packing density. Based on the hardness-packing density model, the reverse .

This test method covers determination of the microindentation hardness of materials. This test method covers microindentation tests made with Knoop and Vickers indenters under test forces in the range from 9.8 ? 10-3 to 9.8 N (1 to 1000 gf).

Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a graded increase, the Mohs scale lacks accuracy and is only a rough measure of hardness. .Micro-hardness testing permits measuring the hardness of a material on a microscopic scale. The Qness Q60 A+ microindenter is a fully automated system with quick and precise positioning relative to the sample. The machine is equipped with three different magnification lenses (10X, 40X, and 65X) and three indenters (Vickers, Knoop and Brinell), which facilitate hardness . Vickers microindentation hardness test was employed to study the mechanical strength of the prepared composites. . as measured by the critical current density J c (> l0 5 A/cm 2), in the presence of . the decrease in porosity may be related to an increase in grain coupling strength and degree of grain orientation of the samples. Awad .

The Leeb hardness tester, also known as the Leeb Rockwell hardness tester, is a com- monly used instrument for measuring the hard ness of metal materials [17]. The principle Extensive research work reveals that the effect of specific external additives on hardness and related properties has been investigated through numerous research groups in the past. . To assess micro-indentation hardness, a standard microindentation testing procedure was utilized. We used a state of art Microhardness Tester [Model: DHV-1000 .

Hardness testing on plastics using various methods Shore hardness Ball indentation hardness Rockwell Instrumented hardness testing More information . Related products. DuraJet G5 Rockwell hardness tester. Test methods. Rockwell . Compression stress value Contact. Contact. ZwickRoell. August-Nagel-Straße 11. 89079 Ulm. Tel: +49 (0)7305 10-0 .

mcat practice test package

technol micro hardness testing

webObituário; Achados e Perdidos; Agenda; Obituário; Achados e Perdidos; Agenda; Inicio; Ao VIVO; Contato; Noticias; . o atleta de 18 anos se destacou nas duas últimas .

how is stress related to density microindentation hardness tester|micro hardness testing